| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | Amphenol FCI Berg |

| Manufacturer Part Number: | Amphenol FCI Berg 61083-184402LF |

| Color: | Natural |

| Series: | BergStak® |

| Gender: | Male |

| Housing Material: | Glass-Filled Liquid Crystal Polymer |

| Number of Contacts: | 180 |

| Number of Rows: | 2 |

| Contact Material: | Brass |

| Contact Plating: | Gold |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -40 °C |

| Pitch: | 0.8 mm |

| Mount Angle: | Straight |

| Mating Cycles: | 100 cycle |

| Flammability Rating: | UL 94V-0 |

| Current Rating: | 0.8 A |

| Voltage Rating: | 100 VAC |

| SKU: | BRG61083-184402LF |

61083-184402LF

| Heilind Number: | BRG61083-184402LF |

| Manufacturer: | Amphenol FCI Berg |

| Manufacturer Number: | 61083-184402LF |

| ECAD Model: |

Specifications

Detailed Description

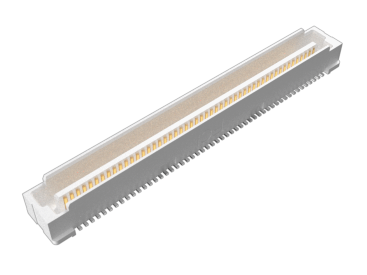

Introducing the BergStak® 61083-184402LF, a high-performance board-to-board connector designed for demanding applications. With a durable housing made of glass-filled liquid crystal polymer, this connector ensures reliable connectivity in harsh environments. Featuring 180 gold-plated brass contacts in a 0.8mm pitch, it offers excellent signal integrity and low contact resistance. Operating at temperatures ranging from -40°C to 125°C, it is suitable for a wide range of industrial and commercial uses. With a straight mount angle and 100 mating cycles, it provides easy installation and long-term durability. RoHS compliant and UL 94V-0 rated for flammability, this connector meets the highest industry standards for safety and environmental responsibility. Whether you're designing a new PCB or upgrading an existing system, the 61083-184402LF is the perfect choice for high-reliability board-to-board connections.

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 04/15/2016 | PCN16002 - Packaging Change. 1. Change the existing material of carrier tape from Polystyrene clear (PS) to Polythylene terephthalate clear (PET). 2. Change existing carrier tape design to prevent deformation of solder tail of terminals. | Download | |||